Thermographing

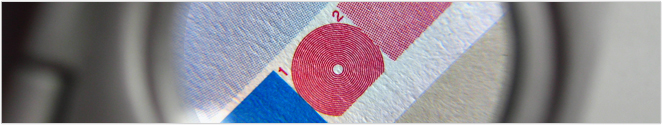

Thermography gives a raised glossy finish to printed products. The thermographic process or thermo as it is more commonly known was developed in the late 1950’s and was popular with the letterpress printer who used the process to enhance invitations, business cards and personal stationery and was a more cost effective alternative to die stamping.

Thermography gives a raised glossy finish to printed products. The thermographic process or thermo as it is more commonly known was developed in the late 1950’s and was popular with the letterpress printer who used the process to enhance invitations, business cards and personal stationery and was a more cost effective alternative to die stamping.

Thermography is a process that applies powder to ink while the ink is wet and is heated and cured to give a high gloss raised image. The printed sheet is passed through a powder hopper on a conveyor belt allowing the powder to stick to the wet ink, the excess thermo powder is then vacuumed off and the sheet continues along the belt into an oven, there the thermo powder becomes molten.

Whilst in it molten state the thermographed sheet is exposed to ultra violet light where it is cured and is instantly dry to the touch.

Advantages of Thermographing

-

A highly cost effective way to add a gloss raised finish to all or part of the printed product.

-

Ideal for Invitations, Business Cards, Letterheads, Compliment Slips, etc.

-

Ideal for use in conjunction with lithography printing, foiling and embossing.

If you require more information please get in touch.